With regards to assembling, the decision between Die Casting Mold and plastic mold can essentially affect the eventual outcome’s quality, cost, and creation proficiency. Figuring out the advantages, applications, and key contemplations of each embellishment cycle is pivotal for choosing the best strategy for your venture.

Understanding Die Casting Mold

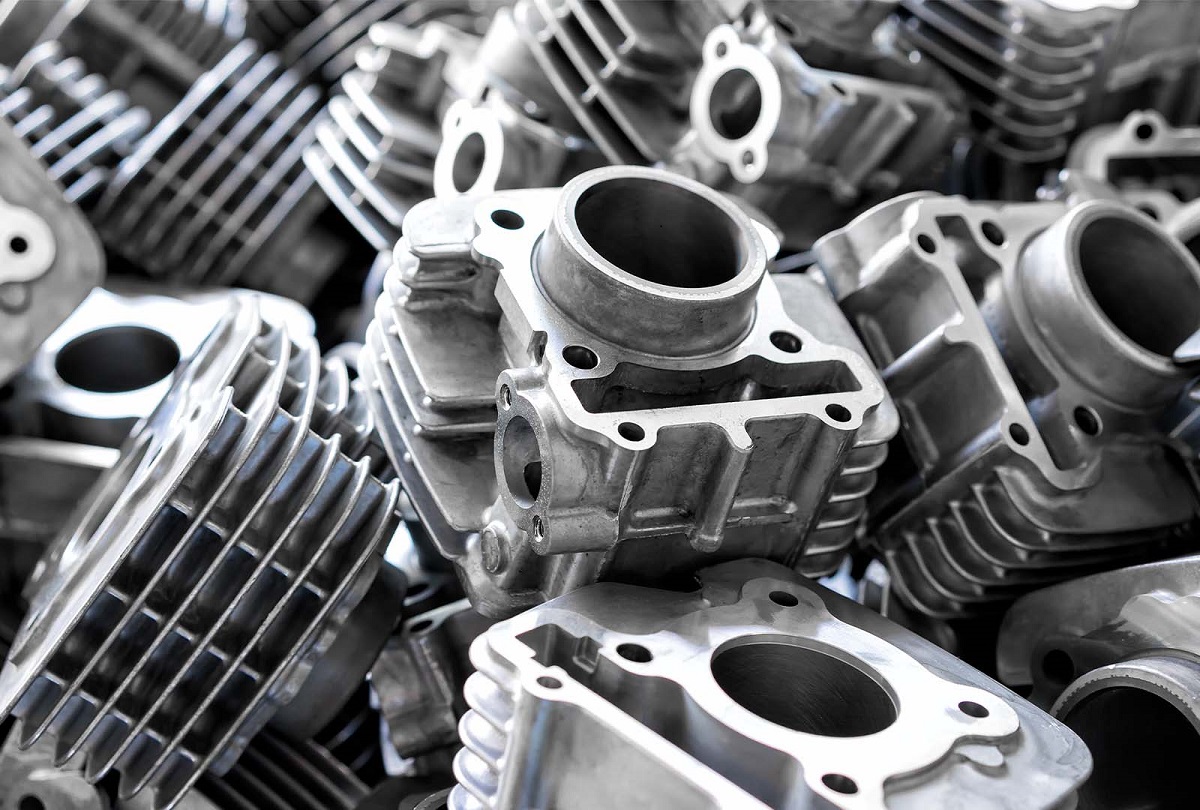

Pass on projecting is a metal projecting interaction that includes driving liquid metal into a shape hole under high tension. The molds, known as kicks the bucket, are commonly produced using steel and are intended to deliver enormous volumes of metal parts with high accuracy and brilliant surface completion.

Advantages of Pass on Projecting Molds:

- High Accuracy and Exactness: Kick the bucket projecting considers the development of parts with tight resistances and many-sided subtleties, making it ideal for complex parts.

- Sturdiness: The molds utilized in bite the dust projecting are profoundly strong and can endure rehashed use, making them appropriate for high-volume creation.

- Prevalent Surface Completion: Pass on cast parts frequently require insignificant post-handling because of their smooth surface completion.

- Strength and Weight: Pass on cast parts are known for their solidarity and can be delivered with meager walls, lessening generally speaking load without compromising primary trustworthiness.

Uses of Pass on Projecting Molds:

- Car Industry: Pass on projecting is generally utilized for delivering motor parts, transmission cases, and other basic car parts.

- Shopper Hardware: Numerous electronic gadget lodgings and inner parts are made utilizing pass on projecting because of the accuracy and strength required.

- Aeronautic trade: The aviation area depends on pass on projecting for delivering lightweight and solid parts that satisfy severe security guidelines.

Key Contemplations:

- Material Constraints: Bite the dust projecting is restricted to non-ferrous metals like aluminum, zinc, and magnesium, which may not be appropriate for all applications.

- Starting Expense: The tooling cost for Die Casting Mold can be high, making it less practical for low-volume creation.

- Intricacy: Planning and keeping up with Die Casting Mold requires ability, as the interaction includes high temperatures and tensions.

Figuring out Plastic Molds

Plastic trim, especially infusion forming, includes infusing liquid plastic into a form pit, where it cools and cements into the ideal shape. Plastic molds are flexible and can be utilized for a great many items.

Advantages of Plastic Molds:

- Adaptability: Plastic molds can be utilized to deliver portions of fluctuating shapes, sizes, and intricacies, making them reasonable for different applications.

- Savvy for High Volumes: While the underlying expense of making plastic molds can be high, the per-unit cost diminishes essentially with huge creation runs.

- Lightweight Parts: Plastic parts are by and large lighter than metal, which can be worthwhile in enterprises like car and customer merchandise.

- Plan Adaptability: Plastic trim considers the joining of different highlights, like surfaces, tones, and complex calculations, straightforwardly into the part.

Uses of Plastic Molds:

Customer Merchandise: From family things to toys, plastic molds are broadly utilized in the creation of ordinary items.

Clinical Gadgets: Plastic embellishment is great for creating clinical gadgets and parts that require high accuracy and cleansing.

Bundling: The bundling business depends vigorously on plastic molds for making holders, covers, and other bundling arrangements.

Key Contemplations:

- Material Determination: The decision of plastic material influences the part’s toughness, adaptability, and cost. Normal materials incorporate ABS, polycarbonate, and polyethylene.

- Ecological Effect: Plastic creation and removal raise natural worries, making it critical to think about manageable practices and materials.

Post-Handling Needs: Contingent upon the application, plastic parts might require extra completing cycles, like managing or painting.

Picking Between Die Casting Mold and Plastic Mold

The choice between pass on projecting molds and plastic molds ought to be founded on a few elements:

- Material Prerequisites: Assuming that the part requires the strength and toughness of metal, Die Casting Mold is the favored technique. For lighter, more adaptable parts, plastic embellishment is much of the time the better decision.

- Creation Volume: Die Casting Mold is more savvy for high-volume creation of metal parts, while plastic embellishment is flexible for both low and high-volume runs.

- Plan Intricacy: The two strategies can oblige complex plans, yet pass on projecting is more qualified for unpredictable metal parts, while plastic trim offers more prominent adaptability in shapes and surfaces.

- Cost Contemplations: The underlying tooling costs for pass on projecting are higher, yet the drawn out cost per unit might be lower for huge scope creation. Plastic embellishment has a lower introductory expense and is conservative for both little and enormous creation runs.

The decision between Die Casting Mold and plastic molds relies upon the particular requirements of your task. Via cautiously assessing the advantages, applications, and key contemplations of each interaction, you can settle on an educated choice that improves your creation proficiency and item quality.

Conclusion

Die Casting Mold include driving liquid metal into a form under high tension, delivering leaves behind high accuracy, sturdiness, and predominant surface completion. They are regularly utilized in the auto, buyer gadgets, and aviation businesses. Notwithstanding, pass on projecting is restricted to non-ferrous metals, includes high introductory expenses, and requires mastery because of its intricacy.

Plastic mold, especially infusion shaping, utilize liquid plastic to make a large number of items. They offer adaptability, cost-viability for high volumes, lightweight parts, and plan adaptability, making them ideal for purchaser merchandise, clinical gadgets, and bundling. In any case, material choice, natural effect, and post-handling needs are significant contemplations.

Picking between the two relies upon material necessities, creation volume, plan intricacy, and cost. Pass on projecting is ideal for metal parts requiring strength and accuracy, while plastic trim is better for lighter, adaptable parts with different applications. The choice ought to be founded on the particular requirements of the venture to improve creation proficiency and item quality.